水和环境

很少有行业像水和环境行业那样多样化。在这里,KELLER Pressure 传感器可以在各种应用中找到。例如,它们被用来测量水深、监测大坝底部的水压、计算流量和调节水位。凭借多年的经验,KELLER Pressure 公司可以在这些领域提供广泛的专业知识。

过滤器

Early Leak Detection on the Construction Site

Without Water Everything Comes to a Halt (EN)

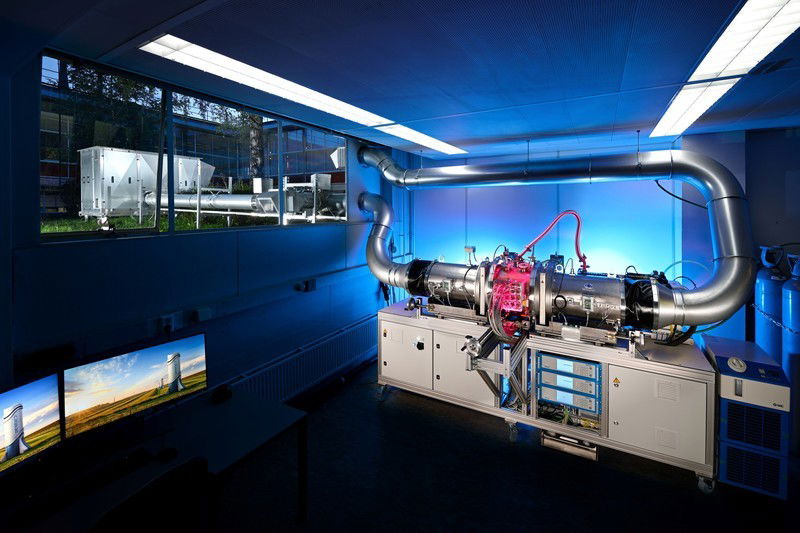

CO2 Recycling (EN)

Pore-Water Pressure Monitoring in Ice-Rich Permafrost (EN)

Upcycling Sensors (EN)

Monitoring the Seabed – The Subtle Distinction (EN)

How to Measure the Pressure on our Eco-System (EN)

Tracking devices for marine animals (EN)

Measuring wave impact pressure (EN)

Cryoegg Glacier Research (EN)

An IoT project with a surprising outcome (EN)

Reducing Drinking Water Losses (EN)

Hydraulic Network Analysis (EN)

Fish Farm Water Level Monitoring (EN)

Pressure Sensors on Water Pipelines (EN)

Intelligent Sewage Overflow Measurement (EN)

Waste Water Level Monitoring (EN)

Continuous Level Measurement (EN)

Avoiding Pump Failures (EN)

Wireless Groundwater Monitoring System (EN)

Cone Penetration Testing (EN)

Water Consumption Monitoring (EN)

Water Monitoring in Open-Pit Mining (EN)

Lithium Brine Production (EN)

Dewatering a Diamond Mine (EN)

Mining in a Diamond Deposit (EN)

Water Wells Level Measurement (EN)

Groundwater Level Measurement (EN)

Reliable Flash Flood Alert (EN)

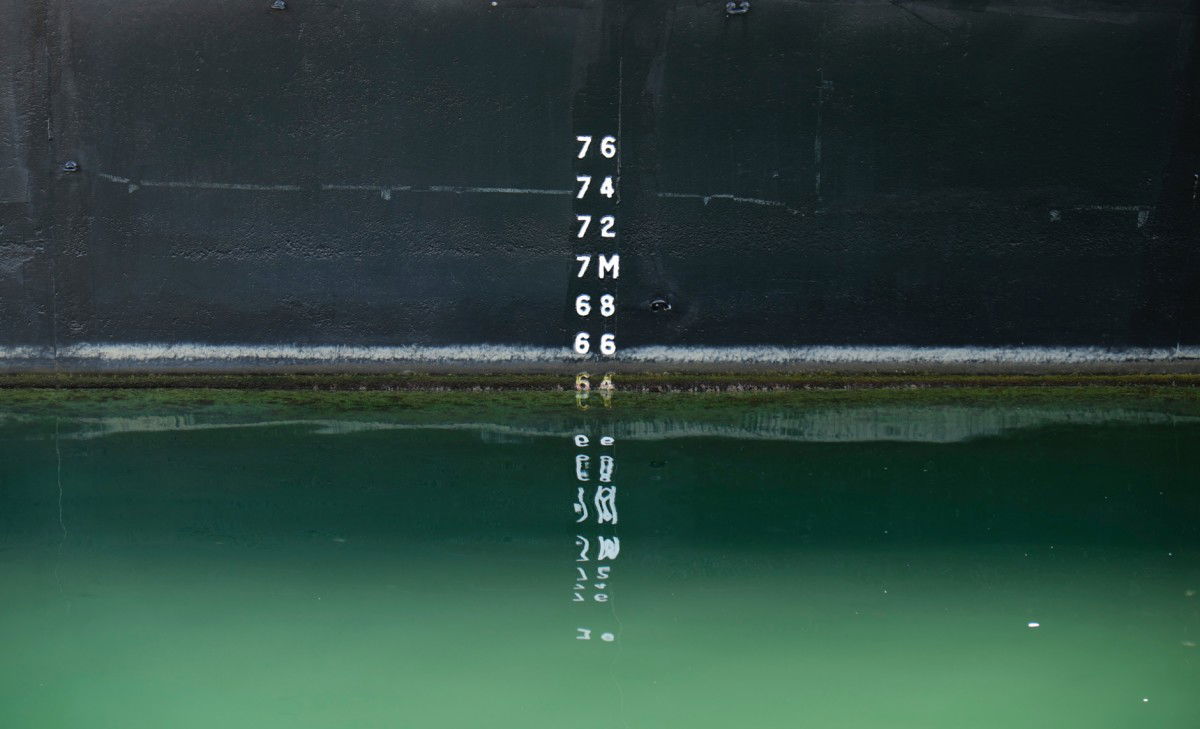

Dam Water Level Monitoring (EN)

Keeping Floods at Bay (EN)

Hydrological Water Level Monitoring (EN)