Expansion Stages – From the Pressure Sensor Capsule to the Connector

13. maggio 2025

A pressure sensor is a pressure measuring device that converts physical pressure into an electrical output variable to make it measurable and analysable. Depending on the manufacturer or language region, pressure sensors are also referred to as pressure measuring cells, pressure transducers, pressure transmitters or pressure measuring transmitters. In this blog, we explain the technical jargon at KELLER Pressure and present the many possible combinations that we offer our customers.

Good to know

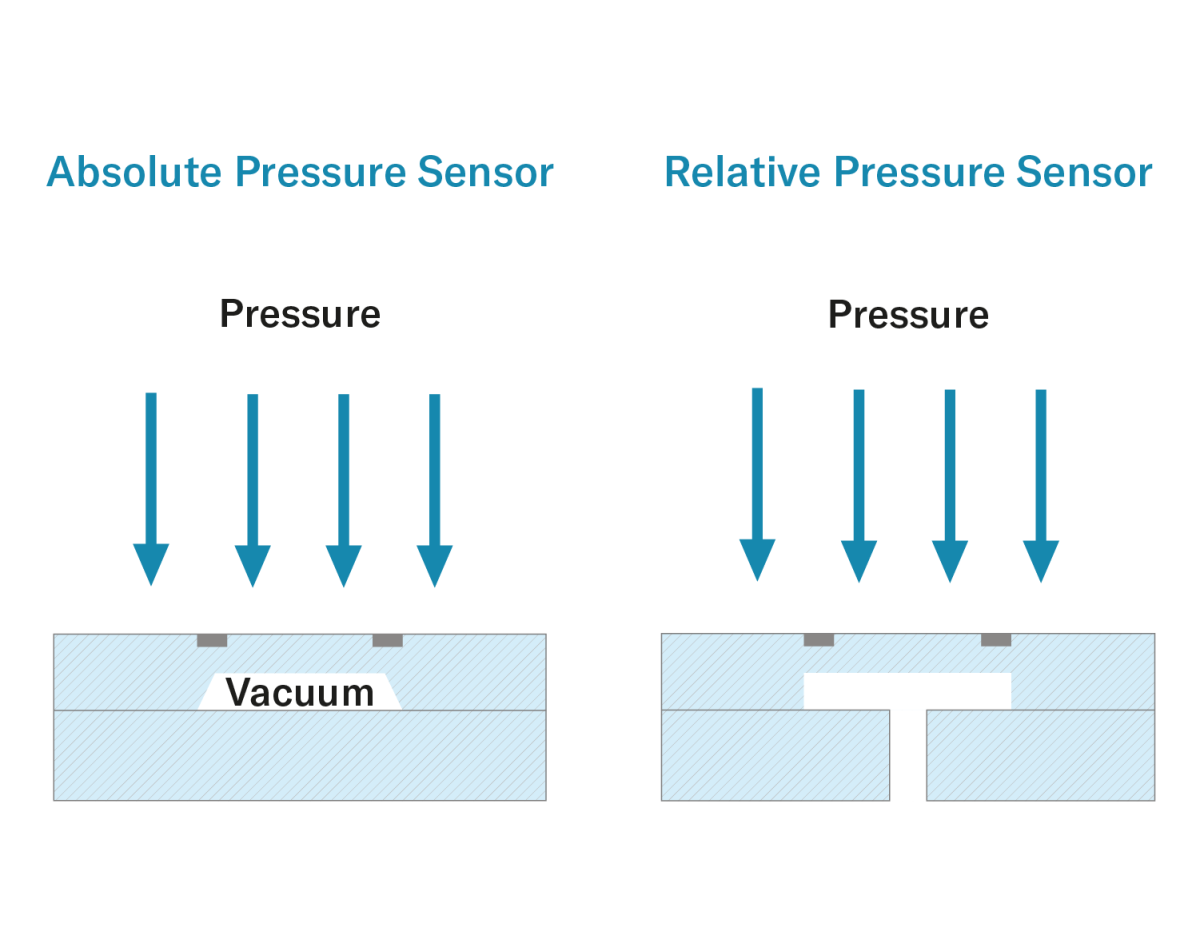

The structure of the pressure transducer has already been discussed in the blog «KELLER Pressure has Reinvented the Wheel». In addition, the different types of pressure are explained in detail in «Pressure Types and What They Mean». This blog builds on the content of the two articles mentioned above and focuses on the difference between a transducer and a transmitter and their respective expansion stages.

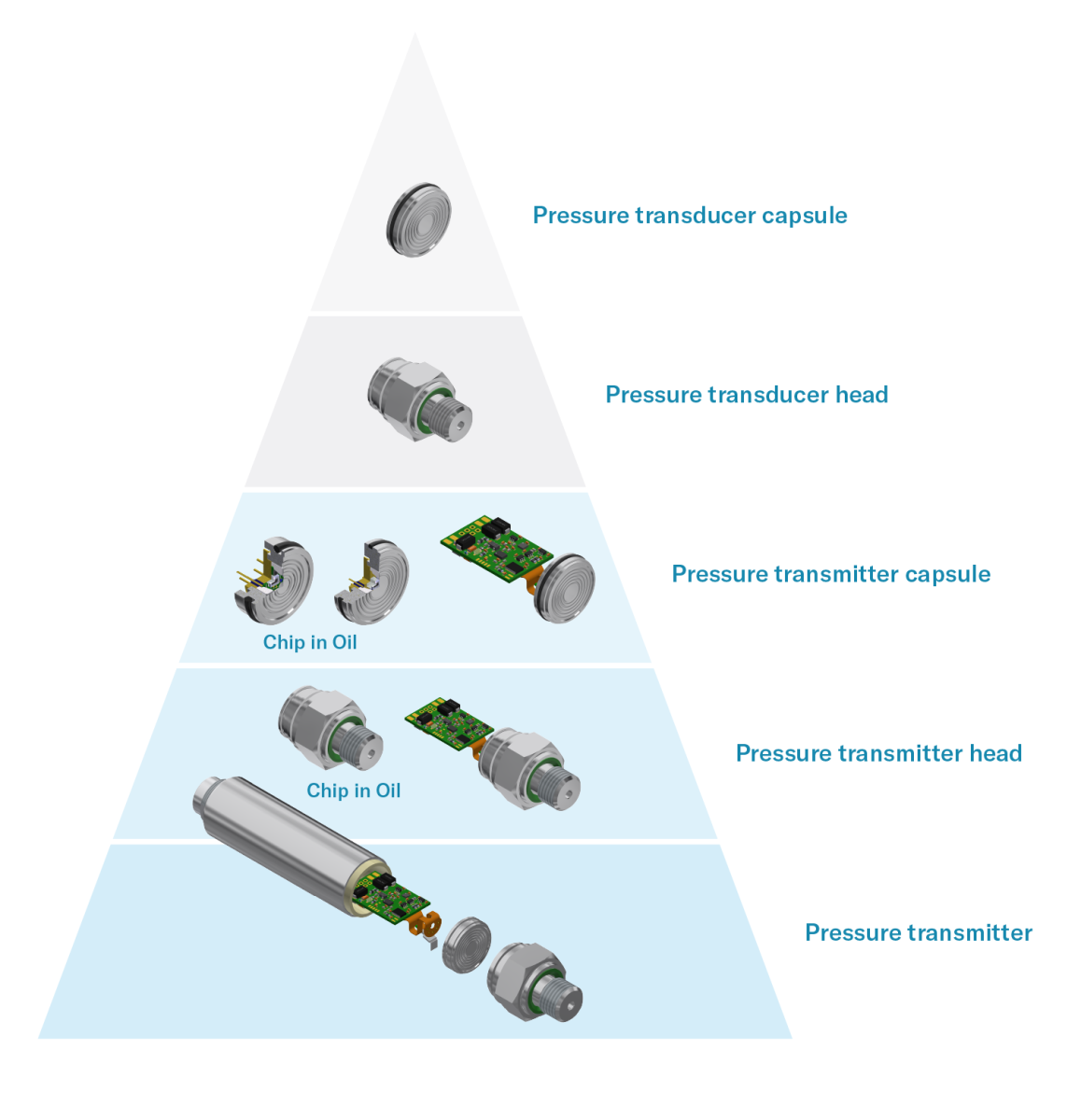

Pressure Transducer Capsule – The Basis

At KELLER Pressure, the term pressure transducer capsule refers to a hermetically sealed, metallic «load cell» in which a pressure sensor chip surrounded by oil is enclosed. In contrast to a pressure transmitter, the output signal of a pressure transducer is neither compensated nor standardised. It shows the original characteristics of the Wheatstone measuring bridge diffused into the pressure sensor chip – unamplified and uncorrected. It is therefore normal for differences to occur in the output signal within a production batch of pressure transducers.

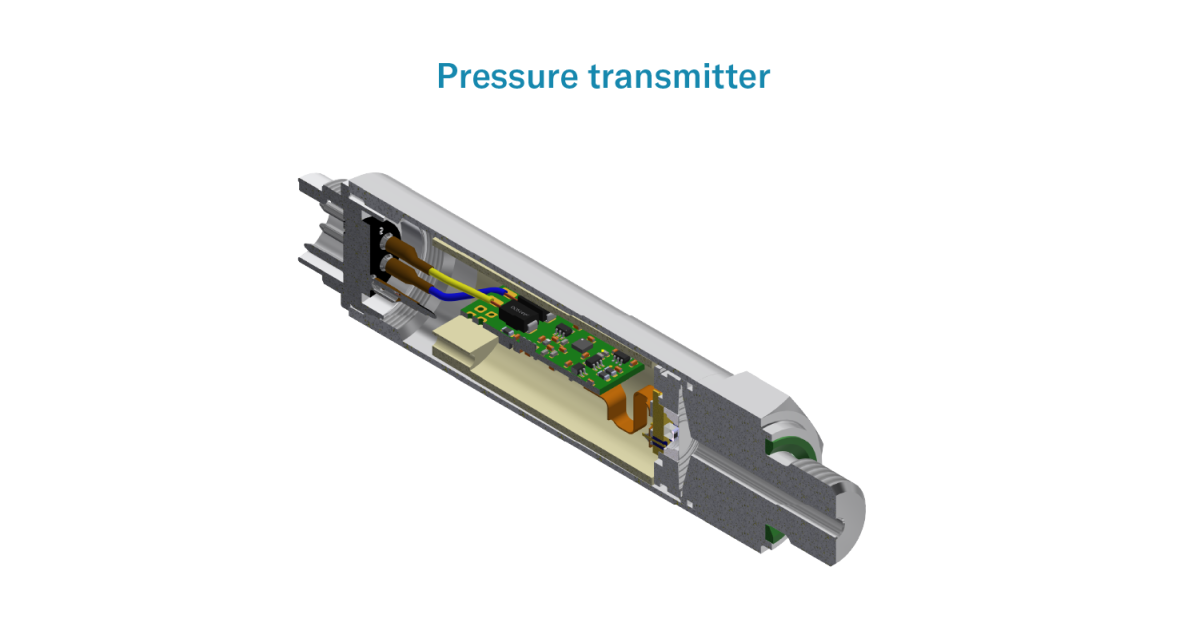

Pressure Transmitter – The Active One

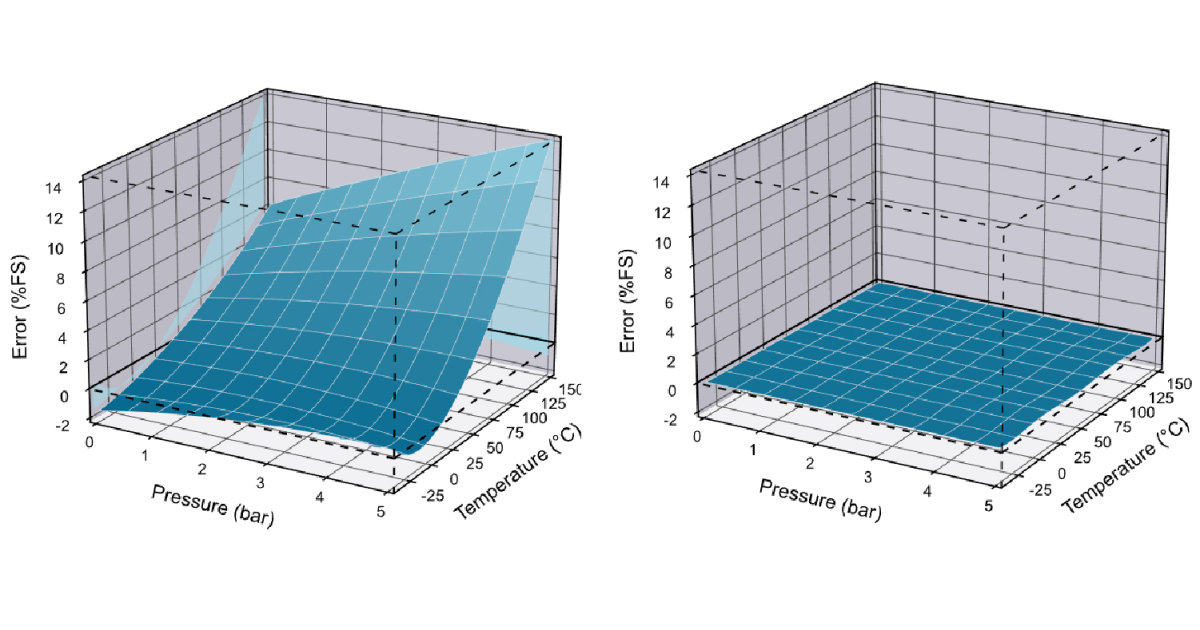

One of KELLER Pressure's core competences is the precise measurement of the characteristics of each individual pressure transducer over the entire pressure and temperature range. Based on the data collected, the signal can be compensated by additional electronics and converted into the output signal required by the customer.

A classic example of this is the still widely used analogue 4...20 mA output signal. While this adjustment used to be carried out manually using adjustable resistors (so-called potentiometers), in most cases it is now carried out by software – quickly, reliably and precisely.

Selection of our Pressure Transmitters

Good to know

In the blog «Even More Accurate Measurements», we explain in more detail what lies behind one of our core competences. The article «Mathematical Compensation Model» takes a closer look at the compensation methodology at KELLER Pressure.

Pressure Sensor Capsule Versus Pressure Sensor Head

The title page of our data sheets uses the phrase «piezoresistive pressure sensor chip, insulated encapsulated» – but what exactly does this mean?

We refer to the typical structure of a pressure transducer as a pressure transducer capsule. The pressure sensor chip inside is hermetically sealed – i.e. encapsulated – and isolated from the medium to be measured by the diaphragm, the metal housing and the glass feedthrough.

We speak of a pressure transducer head when the capsule is combined with a pressure connection – as a rule, both elements are firmly welded together. Compared to the capsule, the pressure transducer head is easier to integrate into an application thanks to the existing thread, hexagon and sealing surface. When using a pressure transducer capsule, on the other hand, the detailed installation instructions provide support when designing and installing the capsule.

Since both terms contain the word «transducer», in both cases it is a passive pressure measuring element without signal conditioning electronics.

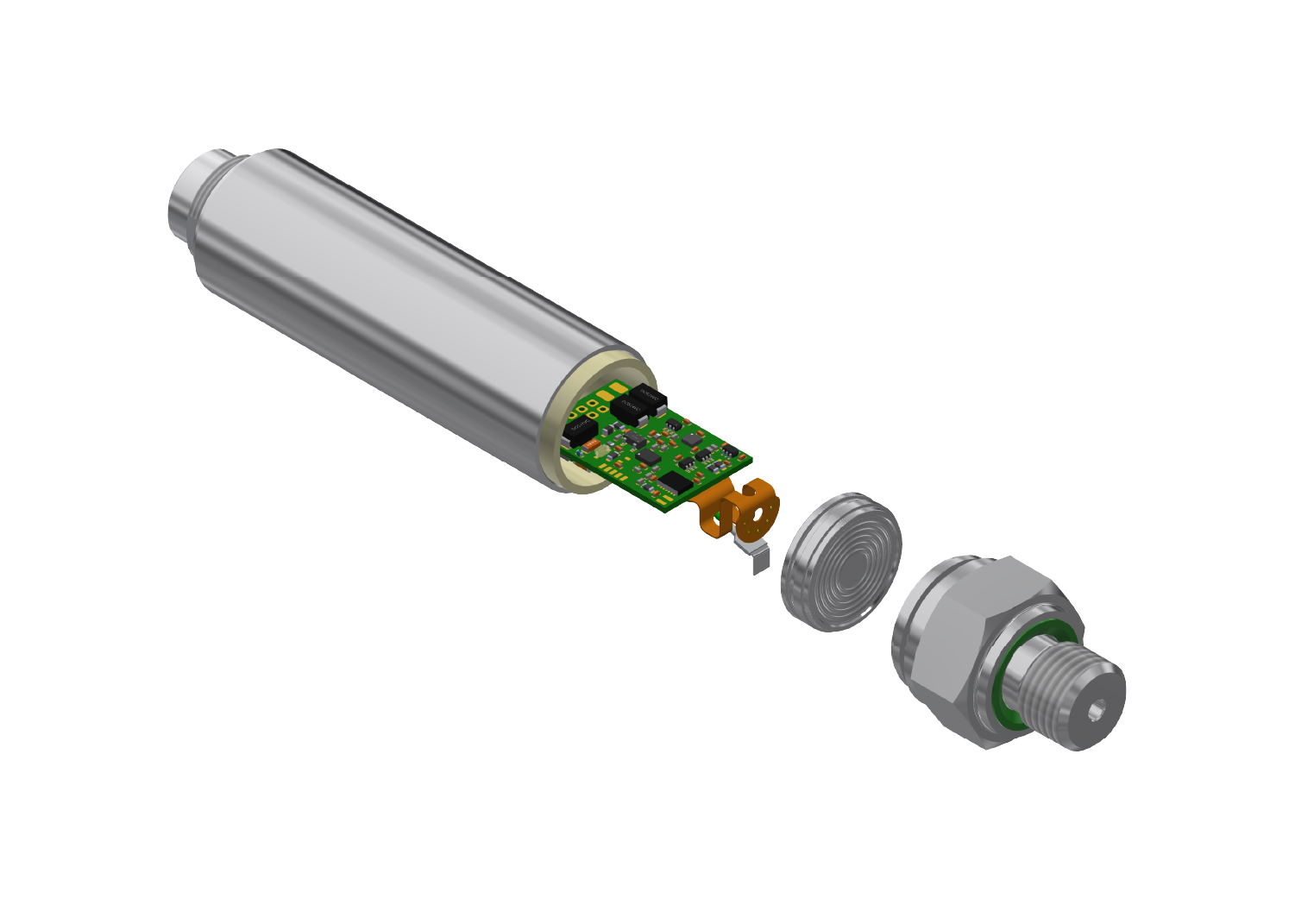

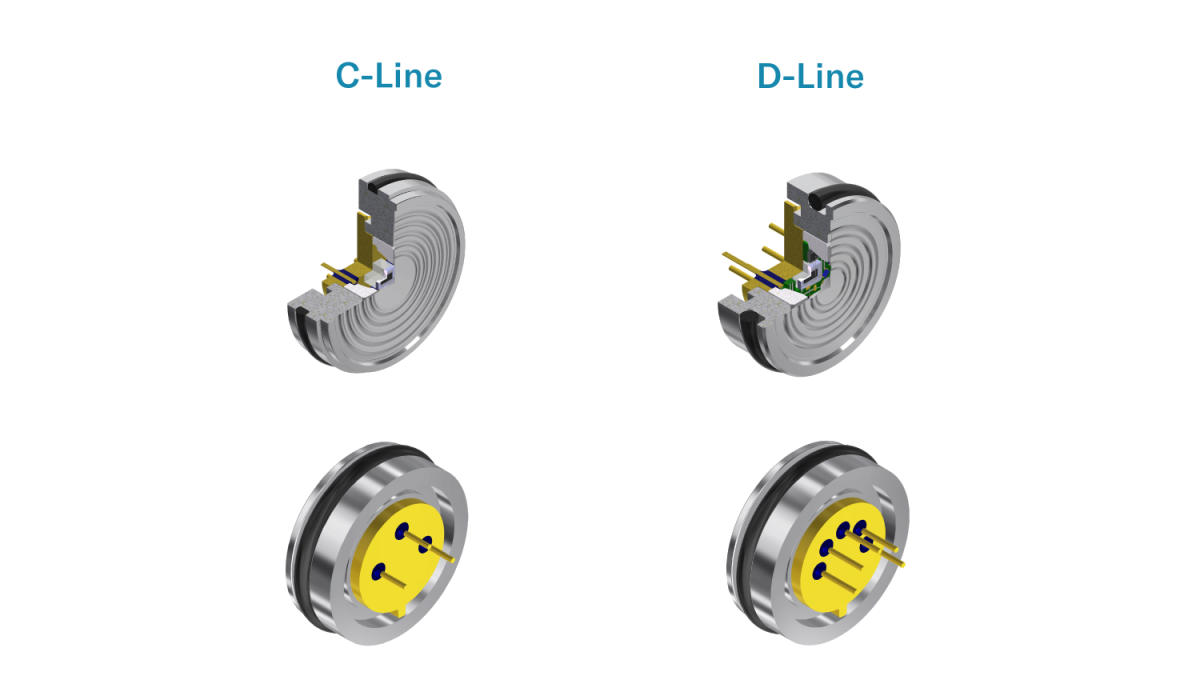

CiO Technology – The Exception

With chip-in-oil technology, as used in the C- and D-Line, the entire electronics are housed directly next to the pressure sensor chip inside the oil-filled metal housing. This eliminates the need for external electronics, enabling a particularly compact design. The products are therefore extremely robust against environmental influences such as moisture, vibrations or shocks.

Thanks to this technology developed by KELLER Pressure, a pressure transmitter can have the outward appearance of a transducer. However, this can lead to confusion, as it is not clear at first glance whether the capsule in question is a pressure transducer with an unamplified signal or a D-Line pressure transmitter. The C-Line is somewhat easier to identify: It is the only product line from KELLER Pressure with a 3-pin glass feed-through.

The main difference between the C-Line and the D-Line lies in the electronics. While the C-Line provides a ratiometric output signal of 0.5...4.5 V, the D-Line converts the signal into a digital I2C signal. The latter is ideal for direct integration into microcontroller-based systems.

Selection of C- and D-Line Series

Custom Solutions – Solutions That Fit Exactly

Our customers' applications are extremely diverse and often require customised solutions – one of KELLER Pressure's key strengths.

One example of many:

A customer requires the performance of the 33X series, but does not have enough space in his application to install a complete transmitter. Our solution: Use a pressure transmitter head – a combination of a transducer head and the associated, exposed compensation electronics. In such cases, the responsibility for housing and protecting the electronics lies with the customer. However, this additional effort is gladly accepted, as the advantages of this extremely compact and customised solution clearly outweigh the disadvantages.

As this concept is difficult to put into words, we have put together an overview of our variants:

The annual evaluation of KELLER Pressure's product portfolio shows the pressure transmitter category has by far the highest sales figures, regardless of the expansion stages.

Selection of a Pressure Transducer Head, a Pressure Transmitter Capsule and a Pressure Transmitter Head

The Most Important Facts at a Glance

A pressure transducer from KELLER Pressure always provides an unamplified, non-standardised output signal. A transmitter, on the other hand, consists of signal conditioning electronics in addition to the transducer to compensate for the characteristics of the transducer and to standardise the output signal.

The most compact transmitters in our portfolio are the C- and D-Line. With these, the entire electronics are totally immersed in the oil, right next to the pressure-measuring silicon chip. They are ideal for applications with very limited installation space.

However, KELLER Pressure not only offers standard transducers and transmitters: we manufacture almost every conceivable combination of capsule or transducer head and customised electronics for our customers – precisely tailored to the respective application.