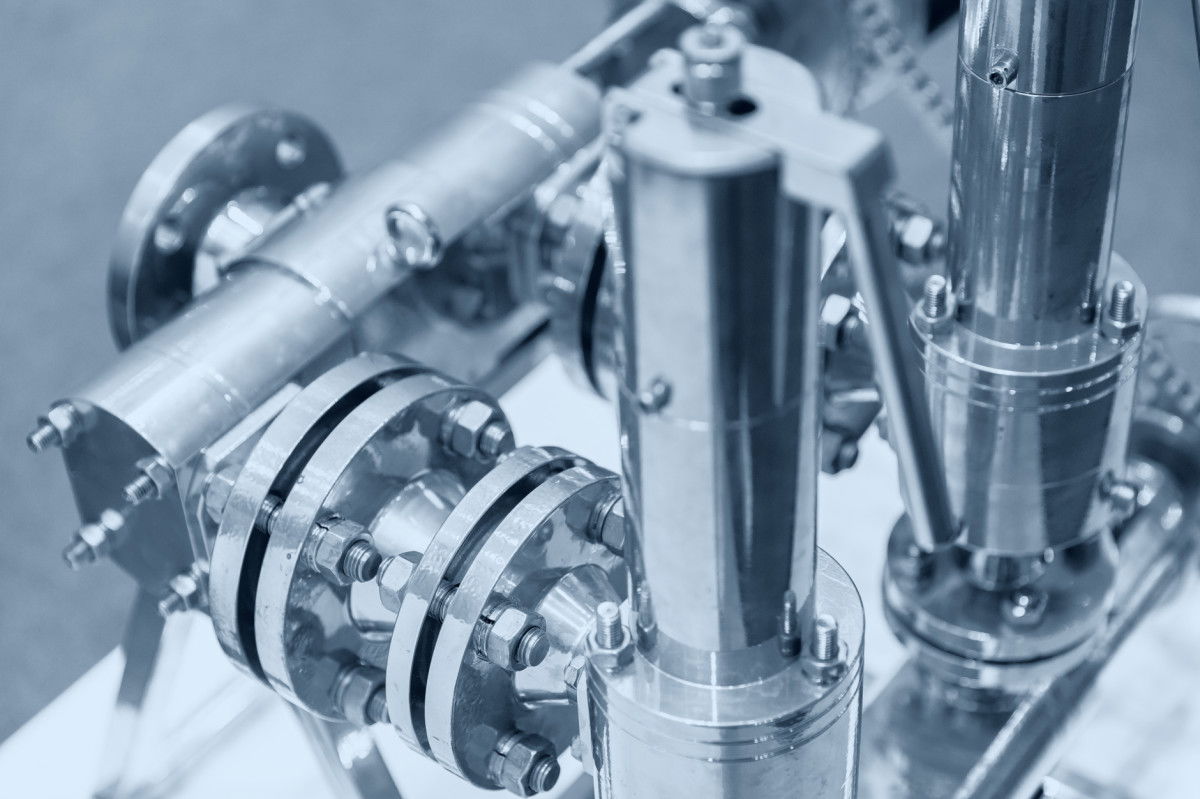

Construção de instalações e dispositivos

A construção de instalações e dispositivos é um ramo tecnológico muito importante que tem o objetivo de construir meios de produção para diferentes setores especializados. Em colaboração com os fabricantes de dispositivos, a KELLER Pressure aplica a sua vasta experiência já durante a fase de desenvolvimento do produto.

Filtros

Pressure Control Means Outstanding Process Control (EN)

Sterilising Bottling Machines (EN)

High-end automation in sensor manufacturing (EN)

Pressure Monitoring for Tempering Machines

Customized differential pressure module (EN)

Large wind turbines full of small sensors (EN)

Contact

SOLUÇÕES PARA AS SUAS APLICAÇÕES

Teremos todo o prazer em aconselhá-lo