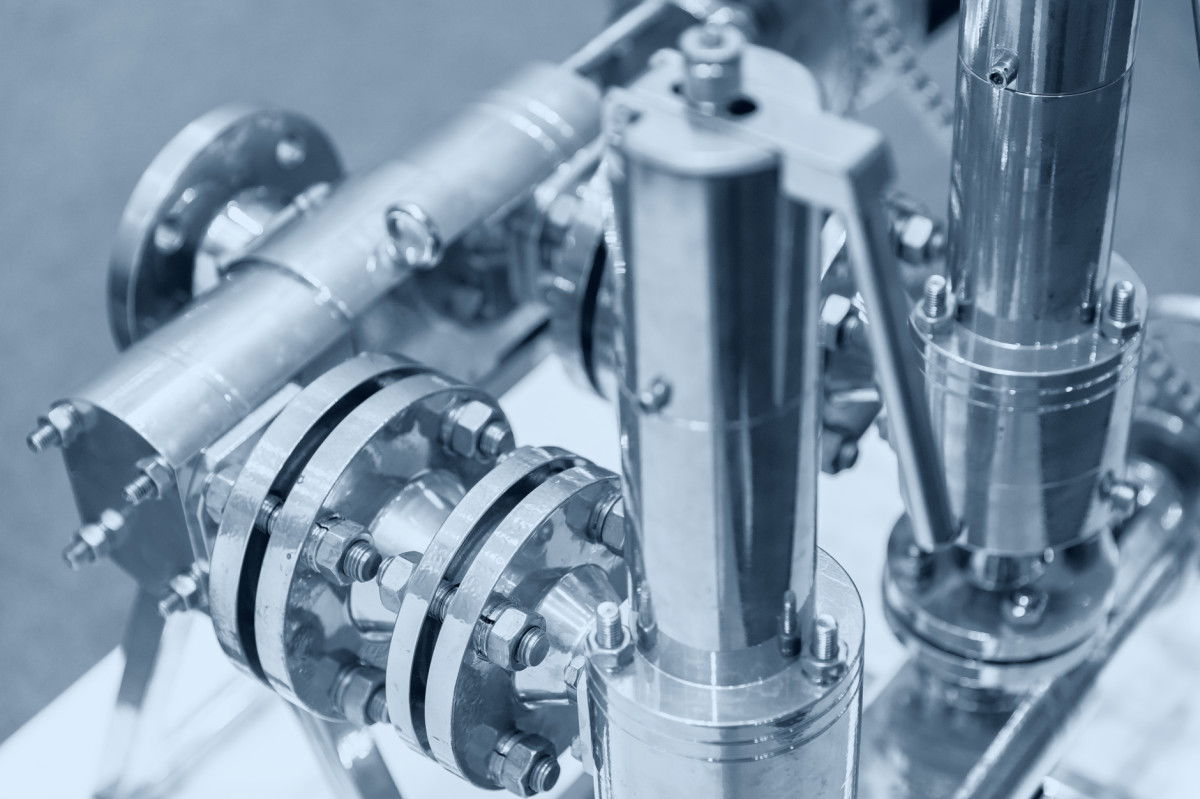

Indústria química, alimentar e farmacêutica

Especialmente na indústria química e farmacêutica, bem como na indústria de produtos alimentares, os processos IoT são muito solicitados. Para a concretização destes processos são necessários sensores, uma vez que apenas um sensor permite detetar estados e realizar ações. Como fabricante líder de sensores de pressão, a KELLER Pressure é o parceiro ideal para a concretização de soluções IoT.

Filtros

Pressure Control Means Outstanding Process Control (EN)

Sterilising Bottling Machines (EN)

Management of medical oxygen (EN)

Tanques de cerveja conectados em rede

Controle dos níveis de água em Piscicultura

Distribuição química

Digital oxygen valve (EN)

Steam sterilisers (EN)

Sensors for the perfect coffee (EN)

Outras aplicações químicas, alimentícias e farmacêuticas

Contact

SOLUÇÕES PARA AS SUAS APLICAÇÕES

Teremos todo o prazer em aconselhá-lo