Quality Starts on a Small Scale

03. June 2025

The right bonding wire for every application

Bonding wires connect the glass feedthrough to the print chip – a crucial step in production that determines the performance and longevity of the measuring cell. Both the manufacturer and the material have a significant influence on how well bonding wires can be processed, how resistant they are to corrosion and how durable they remain in use.

Even the smallest differences in the wire alloy, surface quality or process control can influence the reliability of the connection. Quality therefore begins with the selection of the right bonding wires at the heart of our sensors: the measuring cell.

Research projects by Bond-IQ, a company specialising in wire bonding, such as QUALSI and surf:guide, help to develop a deeper understanding of critical quality factors.

Researching together – efficiently gaining new knowledge

QUALSI and surf:guide are multi-client studies in which several companies participate together, broadening the knowledge gained and whose scope can be easily expanded to include additional topics and questions.

The results of the studies are exclusively available to the participants for five years, after which they are published in full or in part. Practical questions from the participating companies are incorporated directly into the study. Bond-IQ has already successfully completed several such projects in the past.

QUALSI – Investigation of aluminium bonding wires

The QUALSI project investigated various aluminium wires and was completed in April 2024. We were very interested in the study, as aluminium bonding wires are used in many of our sensors.

What is the task of the bonding wire?

The bonding wire is used for the electrical connection between two components – in our case the glass feedthrough and the piezoresistive chip. The wires we use have a diameter of just 25µm, 33µum or 50µm and transmit the measurement signals from the sensor chip via the glass feed-through to the outside, where they are processed further.

QUALSI task definition

- Alloy of the wires (e.g. aluminium, silicon and nickel) and what effects these have on the process window and corrosion resistance

- Difference between soft and hard wire variants in terms of bonding behaviour and service life

- Possible differences between different wire manufacturers

- Differences in the manufacturing process: if there are variations in the batch in terms of tensile load and elongation

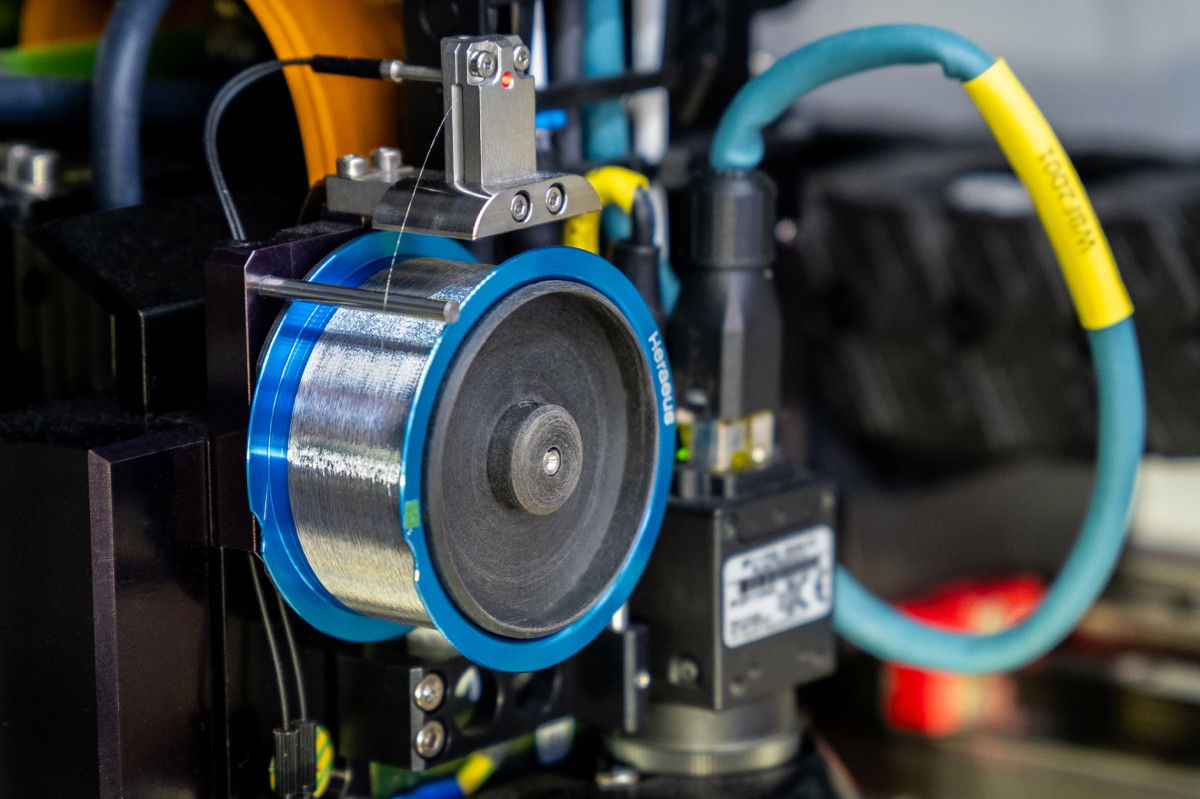

Spool with bonding wire

Size of bonding wire compared with a match

surf:guide – Standards for bond surfaces

The follow-up project surf:guide is in full swing and is focussing on defining suitable surfaces for the wire bonding process. The aim is to develop an industry-wide guideline that can serve as the basis for an industrial standard.

surf:guide task definition

- Specify bond surfaces clearly and reliably

- Monitoring the limits of surface properties through inspection, test and measurement experience

- Process complaints quickly and accurately on the basis of a recognised and industry-standard document

- Accelerate development times and reduce the risk of wrong decisions

- Realise more stable wire bonding processes with fewer errors and process interruptions

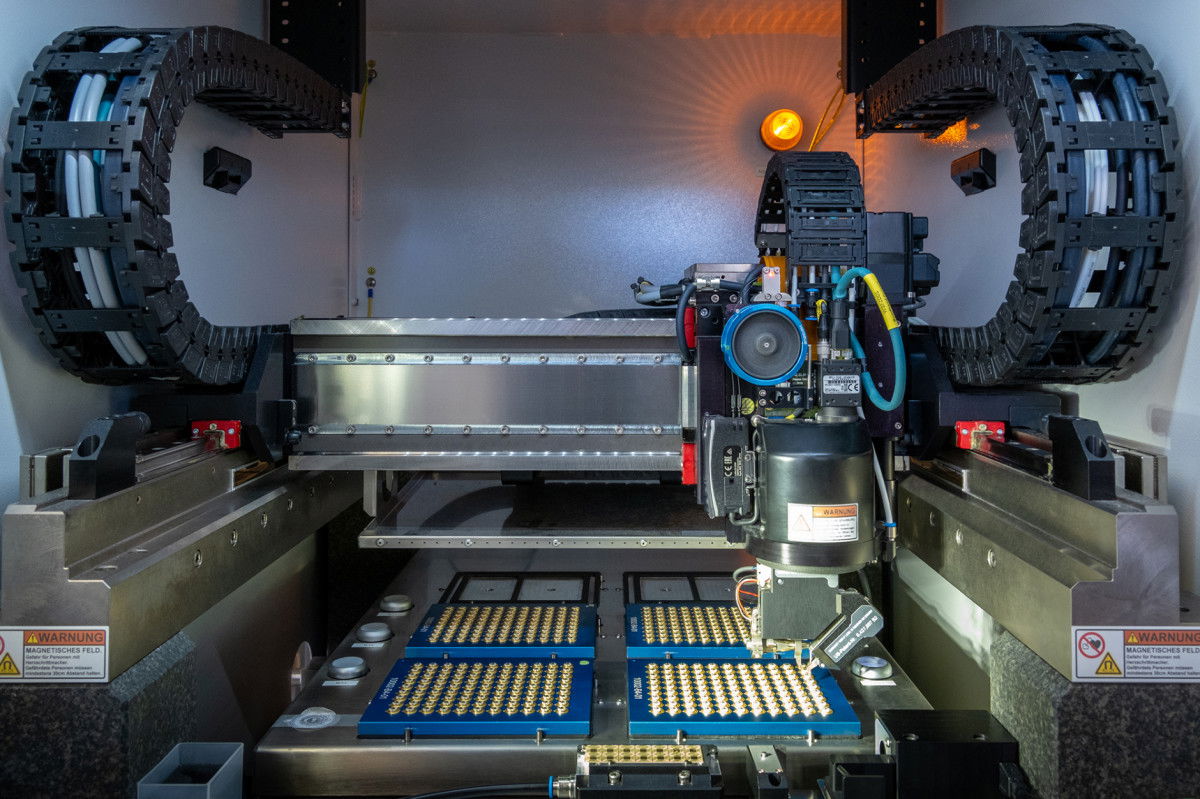

Wire bonding machine

Our conclusion: High benefit – clear decision

QUALSI was our first cross-client project – and will certainly not be the last. The content of the study was practical and scientifically sound. We were regularly provided with meaningful data and analyses.

The decision to take part in surf:guide was an easy one – especially as the knowledge gained far outweighed our own efforts: conducting our own tests would have been far more time-consuming and expensive – both in terms of resources and equipment availability.

Such studies provide us with important impulses for the continuous optimisation of materials and processes. This is exactly what our KELLER Pressure seal of approval promises.

Our sensors bear the KELLER Pressure seal of approval. It stands for piezoresistive pressure measurement technology of the highest quality. The pressure sensors produced in Switzerland are the original, invented by our founder Hannes W. Keller more than 50 years ago.

More about our seal of quality:

https://keller-pressure.com/en/quality-seal